Maximize Powder Coating Efficiency with Gas - Fired Powder Coating Ovens

Gas - fired powder coating ovens are the cornerstone of the powder coating process, playing a crucial role in achieving high - quality finishes. There are two primary types:

Entry - Level Model: Starting at approximately $2500, this model is perfect for small - scale workshops or DIY enthusiasts. It has a straightforward structure and basic temperature - control capabilities, making it easy to operate and maintain.

High - End Industrial Model: Priced from $20000 upwards, this oven is engineered for large - scale industrial production. It incorporates advanced temperature - regulating systems, spacious chambers to accommodate large - sized workpieces, and energy - efficient gas - combustion technology, ensuring both productivity and cost - effectiveness.

These ovens function by burning gas to generate heat, which cures the powder applied to the workpiece. Constructed with top - notch insulation materials, they minimize heat loss, enhancing energy efficiency. Most suppliers also provide comprehensive services, including installation, operation and maintenance training, and after - sales support.

Applications:

Metal Handicraft Industry: The entry - level oven is suitable for curing powder - coated artworks, allowing artisans to achieve a durable and aesthetically pleasing finish.

Automotive Manufacturing: High - end industrial ovens are used to coat car bodies and parts, ensuring long - lasting protection and a sleek appearance.

Metal Window Frame Construction: Depending on production requirements, either type of oven can be utilized to coat window frames, providing corrosion resistance and an attractive finish.

Q: How can I set the temperature accurately?

A: Use the temperature - control panel on the oven. Always refer to the powder manufacturer's guidelines for the optimal curing temperature.

Q: What should I do if I detect a strange smell during operation?

A: Immediately check for gas leaks. If you suspect a leak, turn off the oven and contact a professional technician for inspection and repair.

Q: Can I use the oven for different types of powder?

A: Yes, but it's essential to clean the oven thoroughly between uses of different powder types to prevent cross - contamination.

Q: How often should I clean the oven?

A: Clean the interior and exterior after every 5 - 10 uses. Remove any powder residue and inspect for signs of wear and tear to ensure optimal performance.

Q: How do I select the right gas - fired powder coating oven?

A: Consider factors such as your production volume, budget, and the size and nature of your workpieces. For small - scale projects, an entry - level oven is sufficient. For large - scale production, a high - end industrial oven is more appropriate.

Title:Maximize Powder Coating Efficiency with Gas - Fired Powder Coating Ovens

Link:http://www.hpowdercoating.com/coen/show/646.html

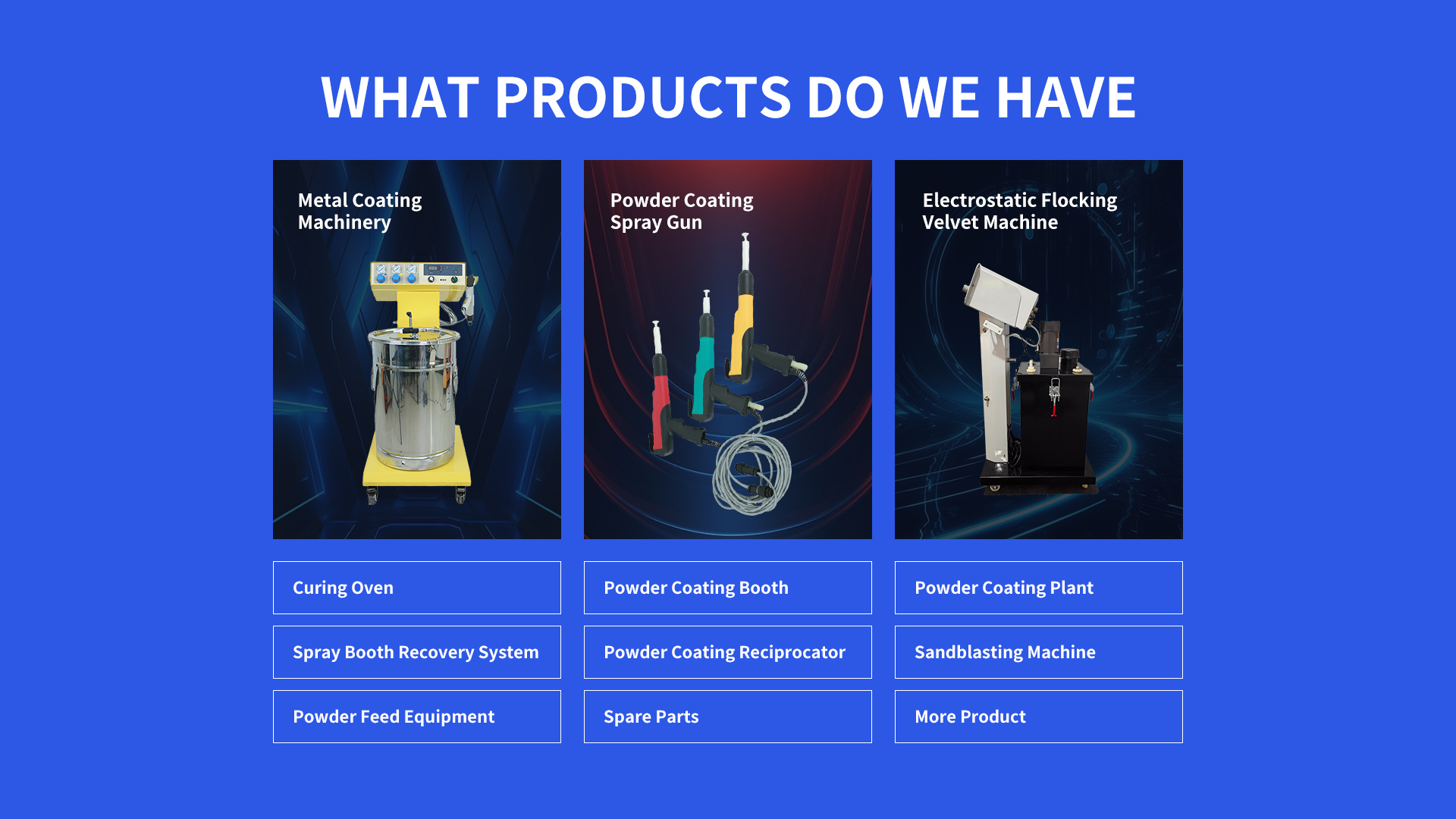

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com